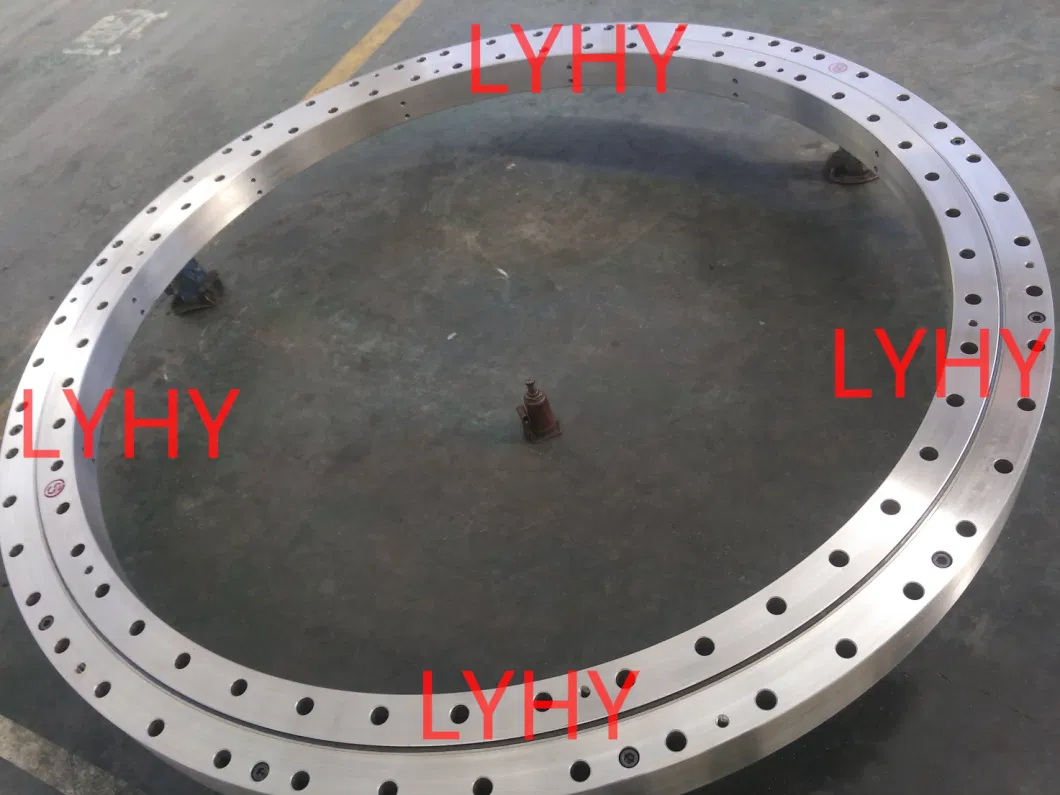

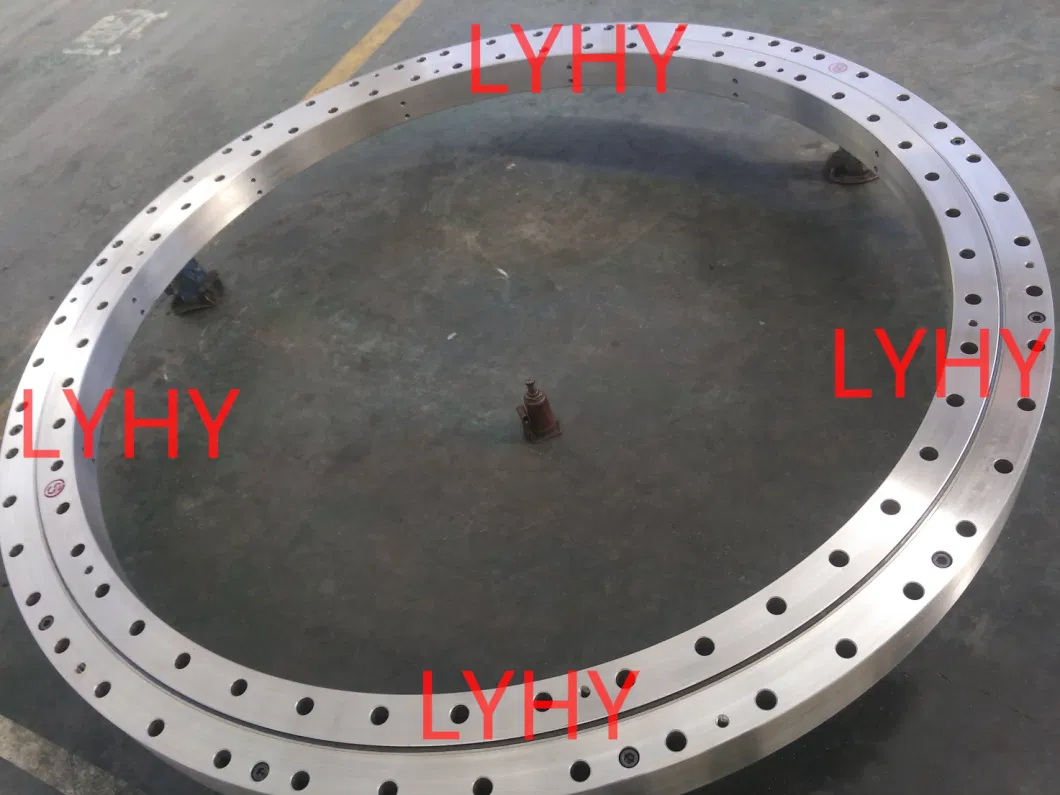

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball slewing ring bearings, roller slewing bearings and precision slewing ring bearings as per customer's different technical requirements.

Slewing ring bearing is also called slewing ring, slewing bearing, turntable bearing, and rotary bearing.

Slewing ring bearing is a bearing that able to bear axial load, radial load and overturning torque. Under normal circumstances, slewing ring bearings have their own mounting holes, lubricant holes and seal holes, to meet the different needs of the various host working under the various conditions;

On the other hand, slewing ring bearing itself has characteristics of compact structure, guide rotating convenient, easy to install and maintaining easily.

Slewing Ring Bearings------Types:

1. four point contact ball slewing ring bearings

2. double row ball four point contact slewing ring bearings(same diameter ball; different diameter ball)

3. cross roller slewing ring bearings

4. triple row cylindrical roller combined slewing ring bearings

5. ball roller combined slewing ring bearings

6. light flanged slewing ring bearings

Slewing Ring Bearings------Technical Data:

1. Material: 42CrMo, 50Mn

2. Precision: P0. P6. P5.

3. Outside diameter: 200~9500mm

4. Cage/retainer: Nylon or aluminum

5. Gear type: non-geared, internal gear and external gear, gear hardened

Slewing Ring Bearings------Applications:

Slewing ring bearings are widely used in industry and known as "the machine joints"

Hereunder is the specific slewing bearing applications

1. Construction machinery (e.g. cranes, excavators, loader, scraper)

2. Metallurgical machinery (e.g. for steel plant)

3. Heavy machinery equipments (e.g. mining machinery, concrete machinery)

4. Marine machinery equipment (e.g. vessel, port hoisting machine, port oil transfer equipment, onshore and offshore crane)

5. Light machinery equipments (e.g. paper machine, plastic, rubber machine, weave machine)

6. Wind power generator

7. Military products (e.g. aerospace machinery)

8. Packing machinery

Slewing Ring Bearings------Packaging Details:

Step 1: Covered with the anti-rust oil

Step 2: wrapped with the plastic film;

Step 3: Packed with Kraft paper and professional belts;

Step 4: Put into wooden box to avoid the rust or the moist;

Remark: Normally, plastic film+ Kraft +belt+ wooden box, but customized packing available,

Our Advantages:

1. Good quality and competitive price

2. Trial order accepted

3. ISO certified company

4. OEM and ODM accepted

5. Manufacturing slewing ring bearings since 2000

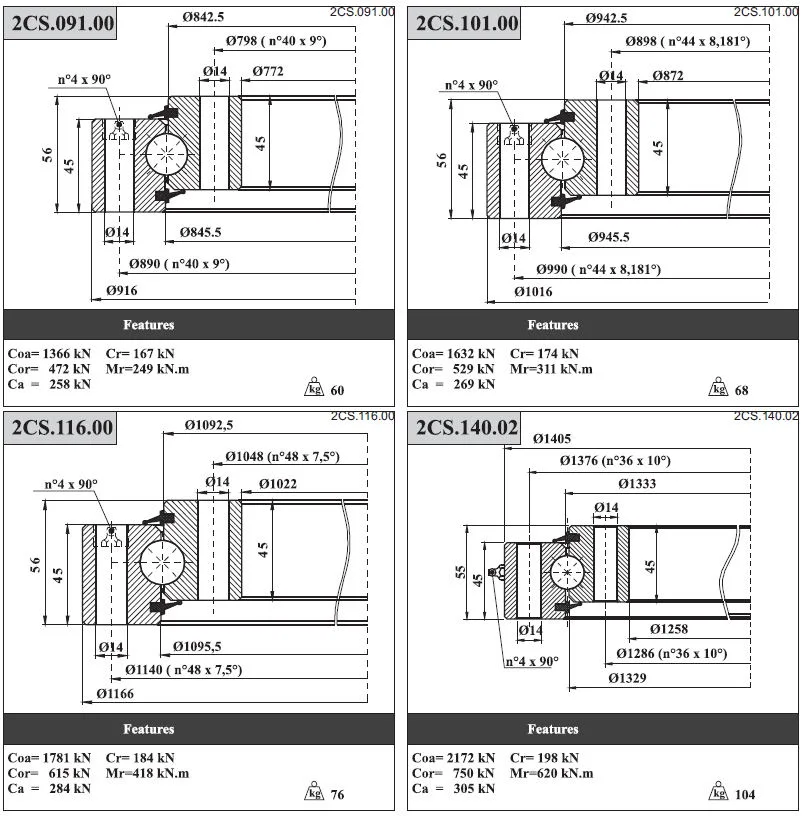

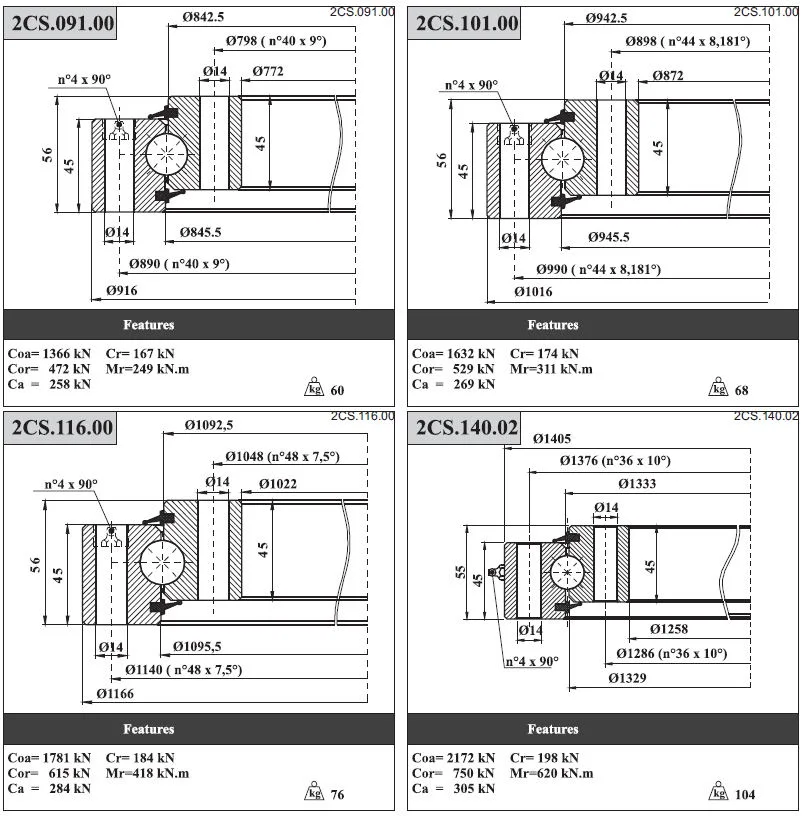

LYHY Slewing bearing models:

2CS.032.00

2CS.039.00

2CS.040.00

2CS.047.00

2CS.048.00

2CS.061.00

2CS.071.10

2CS.081.00

2CS.091.00

2CS.101.00

2CS.116.00

2CS.140.02

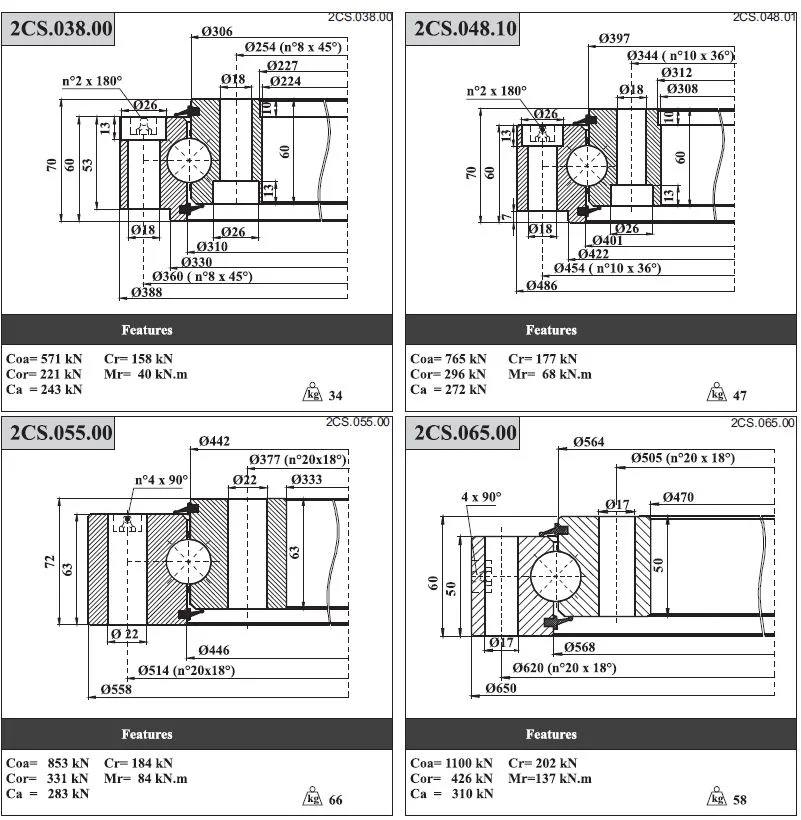

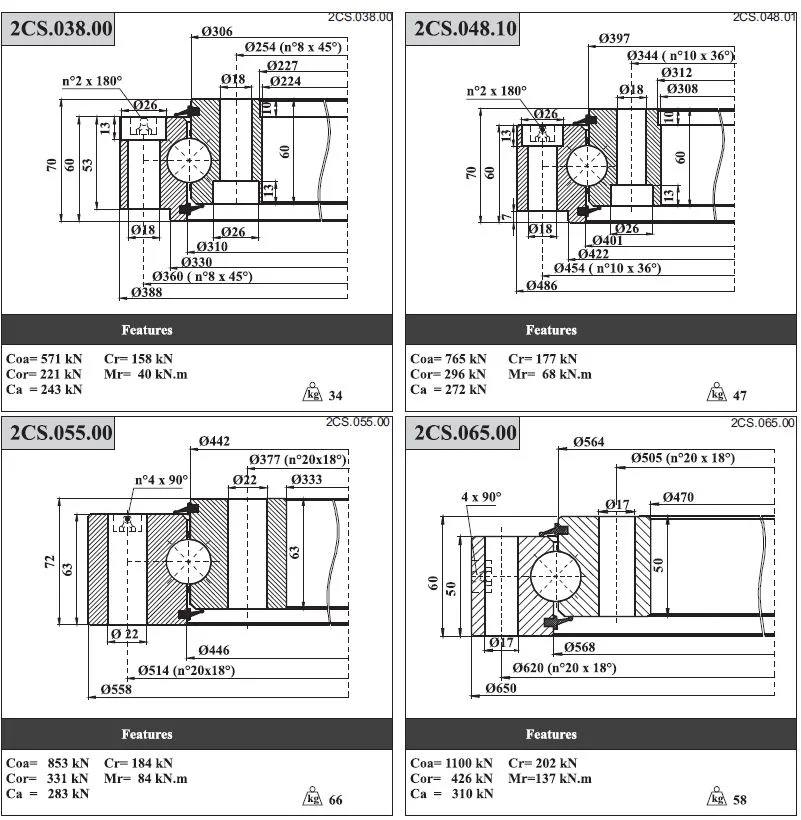

2CS.038.00

2CS.048.10

2CS.055.00

2CS.065.00

2CS.085.00

2CS.095.00

2CS.105.00

2CS.115.00

2CS.125.00

2CS.135.00

2CS.145.00

2CS.155.00

2CS.045.00

2CS.062.10

2CS.071.00

2CS.113.00

Slewing ring bearing is also called slewing ring, slewing bearing, turntable bearing, and rotary bearing.

Slewing ring bearing is a bearing that able to bear axial load, radial load and overturning torque. Under normal circumstances, slewing ring bearings have their own mounting holes, lubricant holes and seal holes, to meet the different needs of the various host working under the various conditions;

On the other hand, slewing ring bearing itself has characteristics of compact structure, guide rotating convenient, easy to install and maintaining easily.

Slewing Ring Bearings------Types:

1. four point contact ball slewing ring bearings

2. double row ball four point contact slewing ring bearings(same diameter ball; different diameter ball)

3. cross roller slewing ring bearings

4. triple row cylindrical roller combined slewing ring bearings

5. ball roller combined slewing ring bearings

6. light flanged slewing ring bearings

Slewing Ring Bearings------Technical Data:

1. Material: 42CrMo, 50Mn

2. Precision: P0. P6. P5.

3. Outside diameter: 200~9500mm

4. Cage/retainer: Nylon or aluminum

5. Gear type: non-geared, internal gear and external gear, gear hardened

Slewing Ring Bearings------Applications:

Slewing ring bearings are widely used in industry and known as "the machine joints"

Hereunder is the specific slewing bearing applications

1. Construction machinery (e.g. cranes, excavators, loader, scraper)

2. Metallurgical machinery (e.g. for steel plant)

3. Heavy machinery equipments (e.g. mining machinery, concrete machinery)

4. Marine machinery equipment (e.g. vessel, port hoisting machine, port oil transfer equipment, onshore and offshore crane)

5. Light machinery equipments (e.g. paper machine, plastic, rubber machine, weave machine)

6. Wind power generator

7. Military products (e.g. aerospace machinery)

8. Packing machinery

Slewing Ring Bearings------Packaging Details:

Step 1: Covered with the anti-rust oil

Step 2: wrapped with the plastic film;

Step 3: Packed with Kraft paper and professional belts;

Step 4: Put into wooden box to avoid the rust or the moist;

Remark: Normally, plastic film+ Kraft +belt+ wooden box, but customized packing available,

Our Advantages:

1. Good quality and competitive price

2. Trial order accepted

3. ISO certified company

4. OEM and ODM accepted

5. Manufacturing slewing ring bearings since 2000

LYHY Slewing bearing models:

2CS.032.00

2CS.039.00

2CS.040.00

2CS.047.00

2CS.048.00

2CS.061.00

2CS.071.10

2CS.081.00

2CS.091.00

2CS.101.00

2CS.116.00

2CS.140.02

2CS.038.00

2CS.048.10

2CS.055.00

2CS.065.00

2CS.085.00

2CS.095.00

2CS.105.00

2CS.115.00

2CS.125.00

2CS.135.00

2CS.145.00

2CS.155.00

2CS.045.00

2CS.062.10

2CS.071.00

2CS.113.00