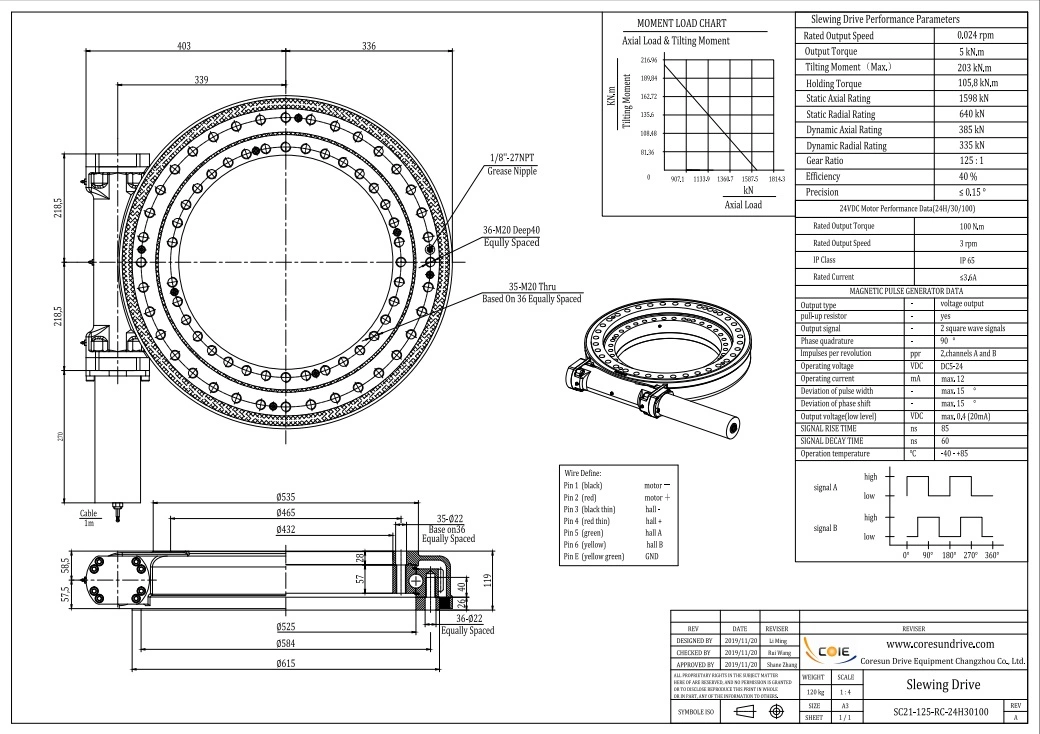

| Model Slewing Bearing | SC21 | Brand | Corresun Drive |

| Holding Torque | 105.8kN.m | Tilting Moment Torque | 203kN.m |

| Self-locking | Yes | Gear Ratio | 125:1 |

| Outer Dia. | 584mm | Inner Dia. | 465mm |

| Efficiency | 40% | Output Torque | 15kN.m |

| Rated Output Speed | 1.2rpm | Colar | Grey |

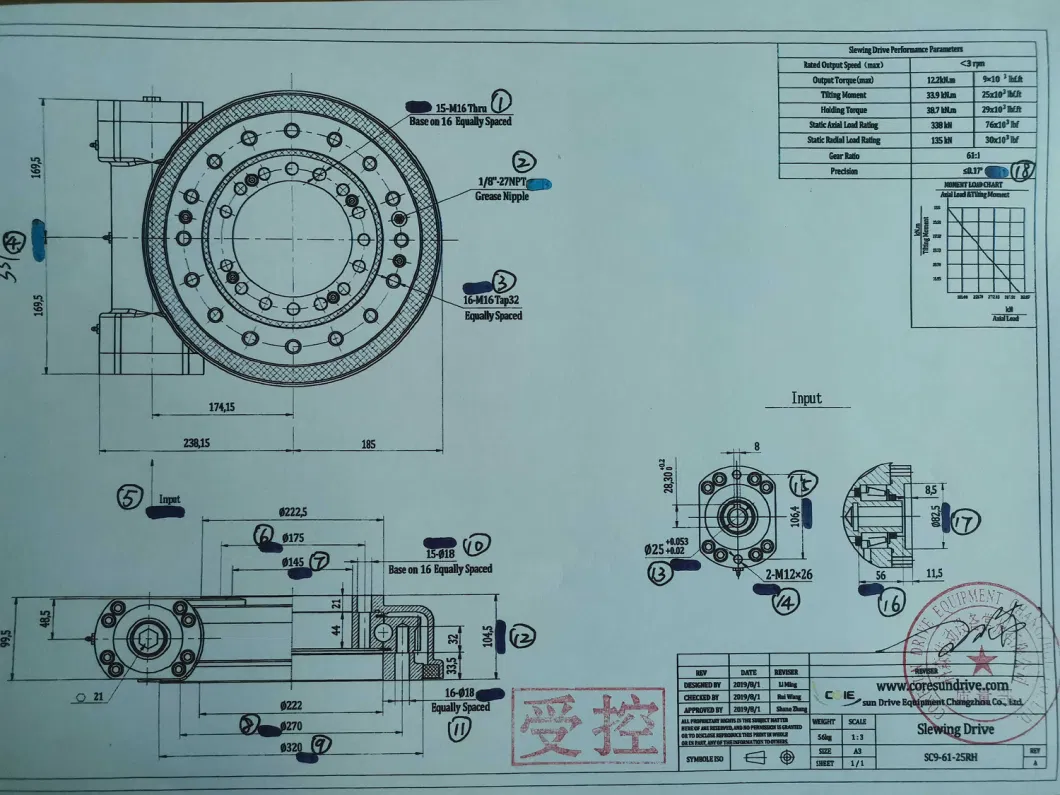

Solar tracker must have smooth, slow and sturdy motion. The tracker should possess high position accuracy and high degree of reliability. These requirements can be attained by specially designed drivers known as slewing drivers.

Horizontal installation

It is advised to mount the slewing drives upside down on the azimuth axis in solar applications for better protection and add protection for the elevation axis. For other applications, the mounting directions shall be based on the evaluation of the protection level and it shall be better for better protection.

Vertical installation

It is advised to mount the slewing drives referring to attached drawing upside in solar applications for better protection. For other applications, the mounting directions shall be based on the evaluation of the protection level and it shall be better for better protection.

The slewing drive is a new type of slewing product, usually called slewing ring, which is usually composed of worm, slewing ring, housing, motor and other components. Since the core components are slewing bearings, they can simultaneously withstand axial forces, radial forces, and overturning moments. Compared with traditional rotary products, the new rotary drive features easy installation, easy maintenance and a greater degree of installation space.

Slewing drive are widely used in PV,CPV,STP solar tracking systems and construction applications including truck cranes, manlifts, turntables, port machinery, modular vehicles, small wind power systems and satellite communications.

Coresun provide the following services to our clients:

1. Finding the right suppliers well suited your requests ( not only cheaper).

2. Providing Dewin Dolphin Report with the real information about the suppliers to help you see the unseen and make the correct decision.

3. Making sure the process of production is according to TS 16949 (IATF 16949)or our common agreement.

4. Providing financial support to our VIP partners to help them getting the big project from their clients.

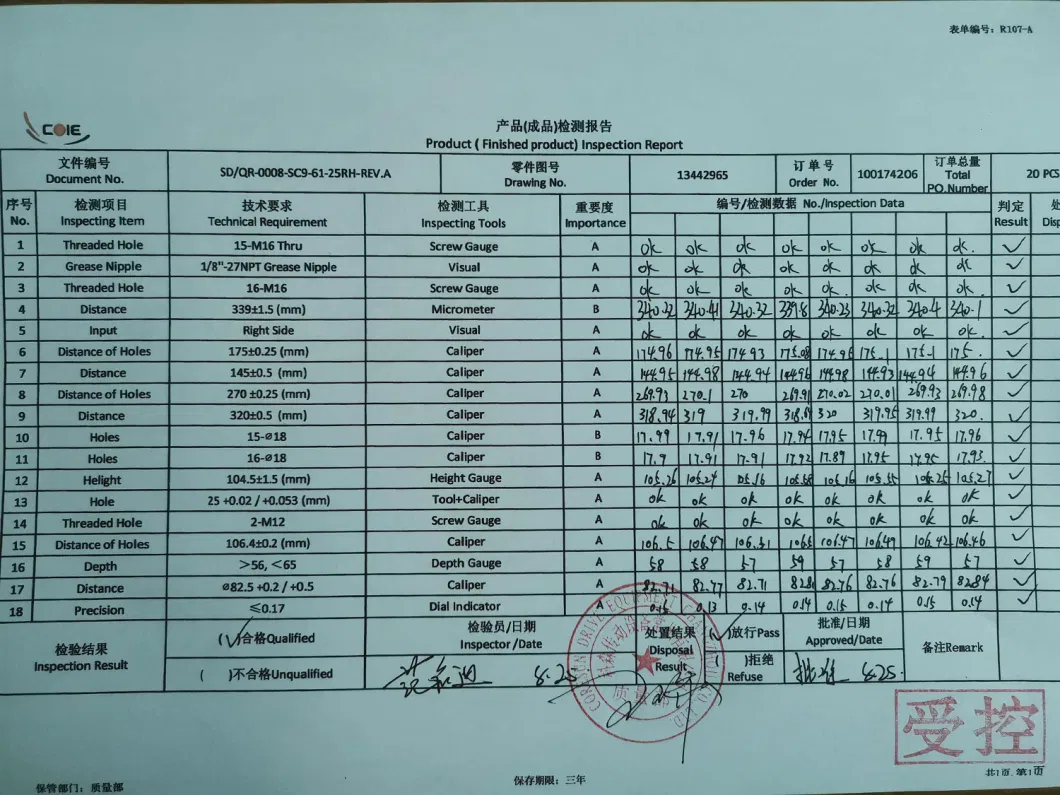

SC21 Slewing Drive Slewing Bearing Worm Testing Report

CONTACT US

It is sincerely looking forward to cooperating with you for and providing you the best quality product & service with all of our heart!